-

sales@tujinmagnet.com

-

+86-18858010843

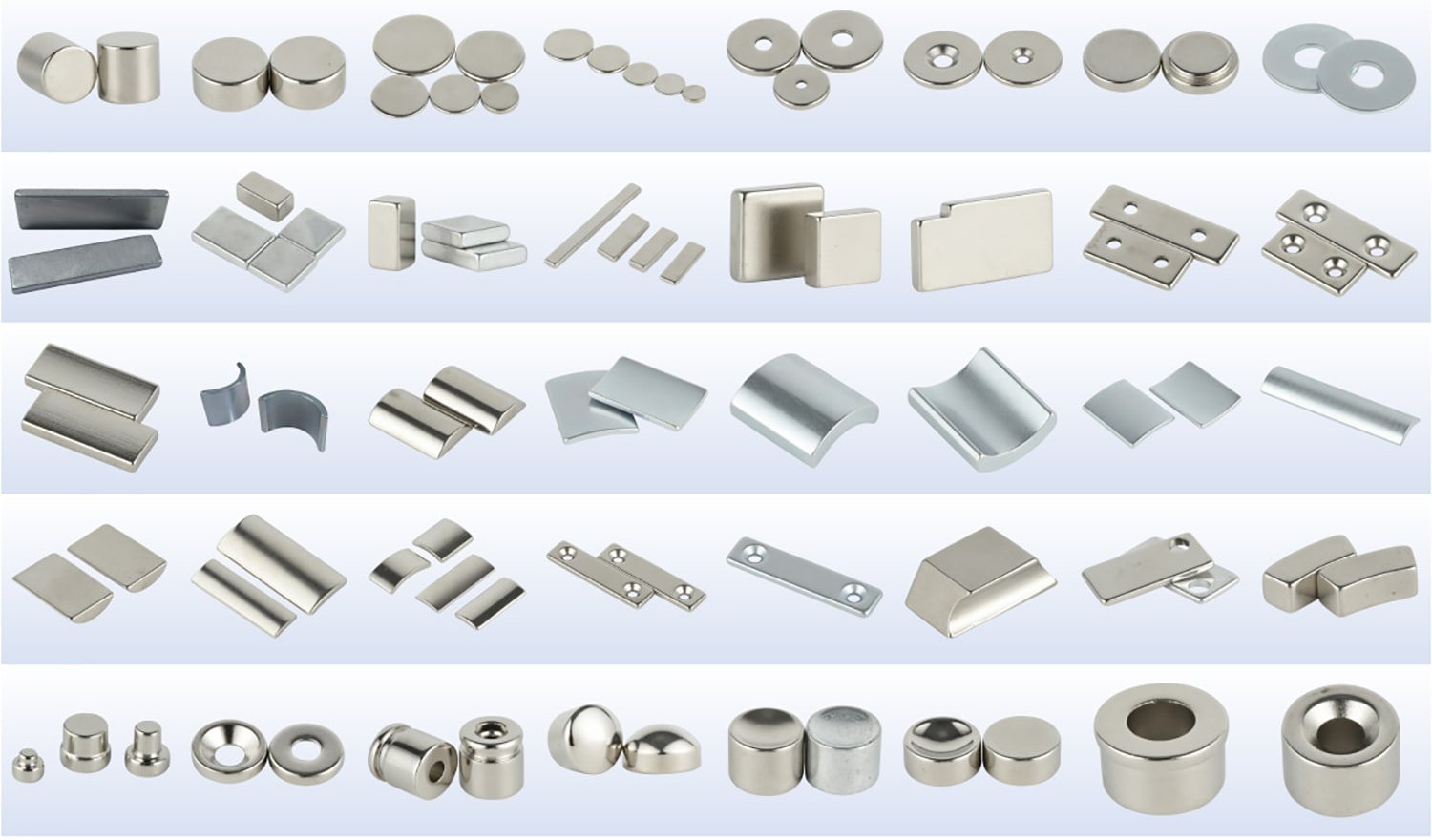

Shape and Size:

Stepped Cube Magnets Neodymium is in the shape of a stepped cube, that is, one or more faces of the cube are cut into steps of different heights. This design not only increases the beauty of the magnet, but also improves its practicality. The magnet is of moderate size, which is easy to carry and operate, and can provide sufficient magnetic field strength. Specifically, its side length and step height can be customized according to the specific needs of customers to meet the needs of different application scenarios.

High-performance permanent magnet material:

NdFeB, as the third-generation rare earth permanent magnet material, has very high magnetic energy product and coercive force.

Corrosion resistance and surface treatment:

NdFeB magnets are mainly composed of iron, neodymium, boron and other elements, and their surfaces are prone to oxidation and rust. Therefore, it is usually necessary to coat, plate or properly surface treat the magnets to improve their corrosion resistance and service life.

Application Fields

Motors and Sensors:

NdFeB magnets are widely used in the fields of motors and sensors. Their high magnetic energy product and coercive force enable motors to have higher efficiency and more stable performance. At the same time, Stepped Cube Magnets Neodymium can also be used as a magnet component in a sensor to detect changes in the magnetic field.

Electronic products:

In electronic products, Stepped Cube Magnets Neodymium can be used to fix or install various components, such as speakers, microphones, etc. Its strong magnetic force and stable performance enable these components to be firmly fixed in the desired position.

Medical and scientific research:

In the fields of medical and scientific research, NdFeB magnets are also widely used. For example, in magnetic resonance imaging (MRI) equipment, magnets are used to generate strong magnetic fields to image the internal tissue structure of the human body. In addition, magnets can also be used for research and application in the fields of magnetic levitation technology and magnetic separation technology.

Products show

Surface Coating & Corrosoin Resistance

|

|

|

|

| Nickel(Ni-Cu-Ni) | Zinc(Zn) | Black Epoxy | Gold |

| Type | Color | Plating Thickness | Working Temperature |

Advantage & Suitable | Salt Spray Resistance | |||||

| Nickel(NiCuNi) | silver | 20-30 um | ≤200 | high oxidation resistance, good glossiness, stable performance, long service life | > 72 hrs | |||||

| Zinc (Zn) | blue white | 10-20 um | ≤160 | suitable for low requirements for surface appearance & oxidation resistance | > 48 hrs | |||||

| Epoxy | black | 10-30 um | ≤120 | suitable for high anti-corrosion and strict atmospheric environment | > 96 hrs | |||||

| Gold | Gold | 5-30 um | ≤200 | suitable for decoration accessories, gift box etc. | > 24 hrs | |||||

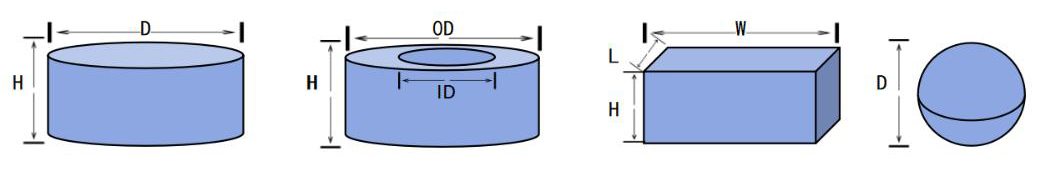

Tolerance

| Standard Product | D.OD | ID | L | W | H |

| <5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

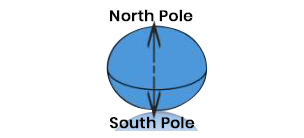

Magnetization Direction

| Disc&Cylinder-through Thickness | Disc&Cylinder-through Diameter | Spheres- through Diameter |

|

Poles on the flat surfaces

|

Poles on the side surfaces |

|

| Block- through Thickness | Block- through Length | Arc- through Diamter |

|

Poles on the larger flat surfaces |

Poles on the smaller flat surfaces |

Poles on outside&inside faces |

| Arc- through Length | Ring- through Surfaces | Ring- through Surfaces |

|

Poles on outside&inside faces |

Planar octupole magnetization |

Planar quadrupole magnetization |

Sintered NdFeB Magnetic Properties

| Grade | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy | Working≤ | |||||||

| Br(KG) | Br(T) | Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) | (BH)max (KJ/ m) |

℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

| Remarks: The maximum working temperature depends on the shape, size, and coating of the magnet, the highest working temperature in the table is the test data for standard sample. | ||||||||||||

Magnetic materials play a crucial role in modern industry and high-tech fields. Among them, neodymiu...

READ MOREDisc magnets, as a common type of permanent magnet, play an important role in our daily lives due to...

READ MOREDisc magnets are becoming increasingly common in our daily lives and industrial sectors due to their...

READ MOREMagnetic materials play a crucial role in modern technology and industry, with Neodymium magnet disk...

READ MOREIn the field of permanent magnet materials, neodymium magnets dominate due to their powerful magneti...

READ MOREIn our daily lives, magnets are present everywhere, from the simple refrigerator clips that hold not...

READ MOREIn modern industry and daily life, there is a class of magnetic materials known as the "King of Magn...

READ MOREIn modern technology, neodymium magnets, known as the "King of Magnets" for their extremely strong m...

READ MORENeodymium magnets, also known as neodymium iron boron (NdFeB), occupy a central position in modern i...

READ MOREIn modern industry and everyday applications, NdFeB magnets are known as the "King of Magnets" for t...

READ MORENdFeB magnets, commonly referred to as neodymium magnets, are the most powerful permanent magnets kn...

READ MORENdFeB magnets, one of the most powerful permanent magnet materials on the market, play a vital role ...

READ MORE