-

sales@tujinmagnet.com

-

+86-18858010843

Shape and Size:

Stepped Countersunk Cylinder Magnets are cylindrical in shape, but not completely uniform, but rather present a stepped design. One end is thicker, the other end is thinner, and the middle part smoothly transitions to form a small groove. In terms of size, the overall height and diameter of the magnet are carefully designed to ensure that it can easily adapt to various application scenarios.

The specific size can be customized according to customer needs.

Counter-sunk design:

One end of the magnet adopts a countersunk design, which allows the magnet to fit more closely to the surface of the object when installed, reduces the impact of the raised part on the use environment, and also makes the magnet more stable during the connection and fixing process, and is not easy to fall off or shake.

Details:

The surface of the magnet is smooth and flawless, with no obvious scratches or depressions. The stepped design makes the magnet more layered visually, and also increases its contact area with other objects, thereby improving the stability of the magnetic force.

Material

Stepped Countersunk Cylinder Magnets are made of high-quality neodymium iron boron (NdFeB) magnetic material. NdFeB has excellent properties such as high remanence, high coercivity and high magnetic energy product. NdFeB magnets not only have strong magnetic force, but also have good mechanical properties and corrosion resistance, which can meet the use requirements in various complex environments.

Manufacturing process

It is manufactured using advanced powder metallurgy and sintering technology. During the production process, it undergoes multiple processes of fine processing and strict quality control to ensure the dimensional accuracy, shape consistency and magnetic stability of the product.

Magnetic properties and stability

Magnetic properties

This product has excellent magnetic properties, such as high magnetic energy product, high remanence and high coercivity. These magnetic properties parameters determine the attraction and stability of the magnet, which can meet the needs of various application scenarios.

Stability

The magnet can maintain stable magnetic properties during use and is not easily disturbed by the external environment. In high temperature, humid or highly corrosive environments, the magnet can still maintain its original magnetic force and shape, and there will be no obvious demagnetization or deformation.

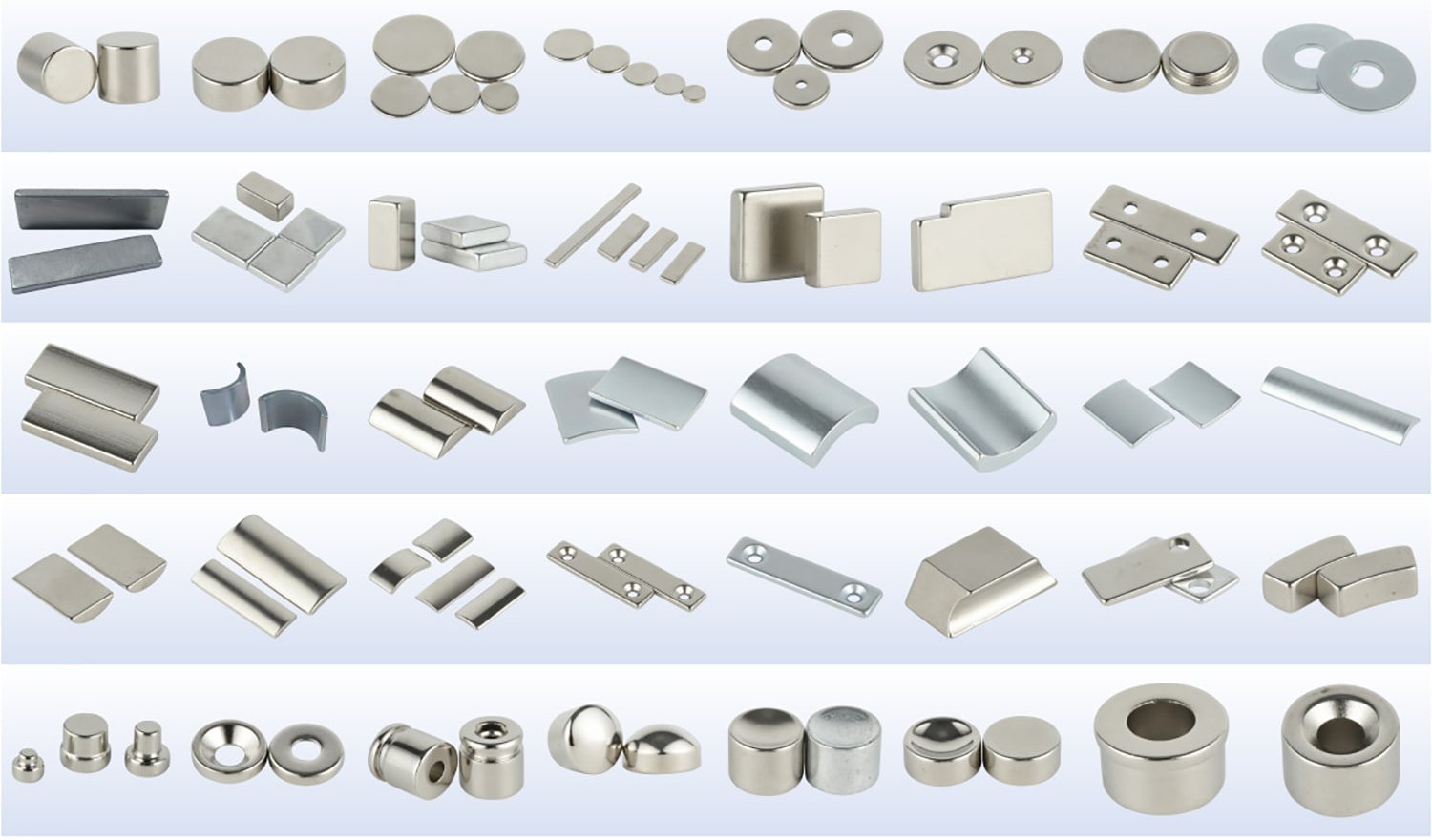

Products show

Surface Coating & Corrosoin Resistance

|

|

|

|

| Nickel(Ni-Cu-Ni) | Zinc(Zn) | Black Epoxy | Gold |

| Type | Color | Plating Thickness | Working Temperature |

Advantage & Suitable | Salt Spray Resistance | |||||

| Nickel(NiCuNi) | silver | 20-30 um | ≤200 | high oxidation resistance, good glossiness, stable performance, long service life | > 72 hrs | |||||

| Zinc (Zn) | blue white | 10-20 um | ≤160 | suitable for low requirements for surface appearance & oxidation resistance | > 48 hrs | |||||

| Epoxy | black | 10-30 um | ≤120 | suitable for high anti-corrosion and strict atmospheric environment | > 96 hrs | |||||

| Gold | Gold | 5-30 um | ≤200 | suitable for decoration accessories, gift box etc. | > 24 hrs | |||||

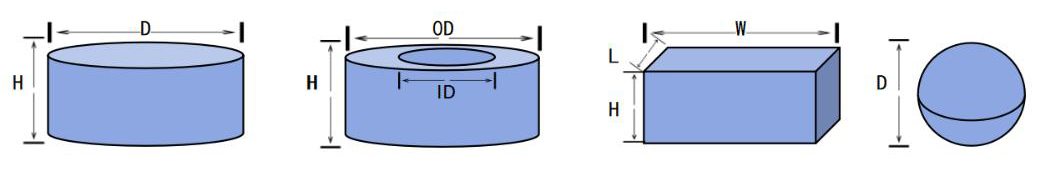

Tolerance

| Standard Product | D.OD | ID | L | W | H |

| <5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

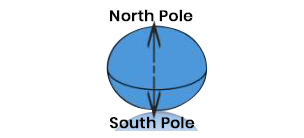

Magnetization Direction

| Disc&Cylinder-through Thickness | Disc&Cylinder-through Diameter | Spheres- through Diameter |

|

Poles on the flat surfaces

|

Poles on the side surfaces |

|

| Block- through Thickness | Block- through Length | Arc- through Diamter |

|

Poles on the larger flat surfaces |

Poles on the smaller flat surfaces |

Poles on outside&inside faces |

| Arc- through Length | Ring- through Surfaces | Ring- through Surfaces |

|

Poles on outside&inside faces |

Planar octupole magnetization |

Planar quadrupole magnetization |

Sintered NdFeB Magnetic Properties

| Grade | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy | Working≤ | |||||||

| Br(KG) | Br(T) | Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) | (BH)max (KJ/ m) |

℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

| Remarks: The maximum working temperature depends on the shape, size, and coating of the magnet, the highest working temperature in the table is the test data for standard sample. | ||||||||||||

Magnetic materials play a crucial role in modern industry and high-tech fields. Among them, neodymiu...

READ MOREDisc magnets, as a common type of permanent magnet, play an important role in our daily lives due to...

READ MOREDisc magnets are becoming increasingly common in our daily lives and industrial sectors due to their...

READ MOREMagnetic materials play a crucial role in modern technology and industry, with Neodymium magnet disk...

READ MOREIn the field of permanent magnet materials, neodymium magnets dominate due to their powerful magneti...

READ MOREIn our daily lives, magnets are present everywhere, from the simple refrigerator clips that hold not...

READ MOREIn modern industry and daily life, there is a class of magnetic materials known as the "King of Magn...

READ MOREIn modern technology, neodymium magnets, known as the "King of Magnets" for their extremely strong m...

READ MORENeodymium magnets, also known as neodymium iron boron (NdFeB), occupy a central position in modern i...

READ MOREIn modern industry and everyday applications, NdFeB magnets are known as the "King of Magnets" for t...

READ MORENdFeB magnets, commonly referred to as neodymium magnets, are the most powerful permanent magnets kn...

READ MORENdFeB magnets, one of the most powerful permanent magnet materials on the market, play a vital role ...

READ MORE