-

sales@tujinmagnet.com

-

+86-18858010843

Rare Earth Magnets NdFeB is composed of neodymium, iron, boron and other elements. It is manufactured through advanced powder metallurgy and sintering technology. It has extremely high magnetic energy product and coercive force. It is one of the permanent magnet materials with strong magnetic properties in commercial magnets.

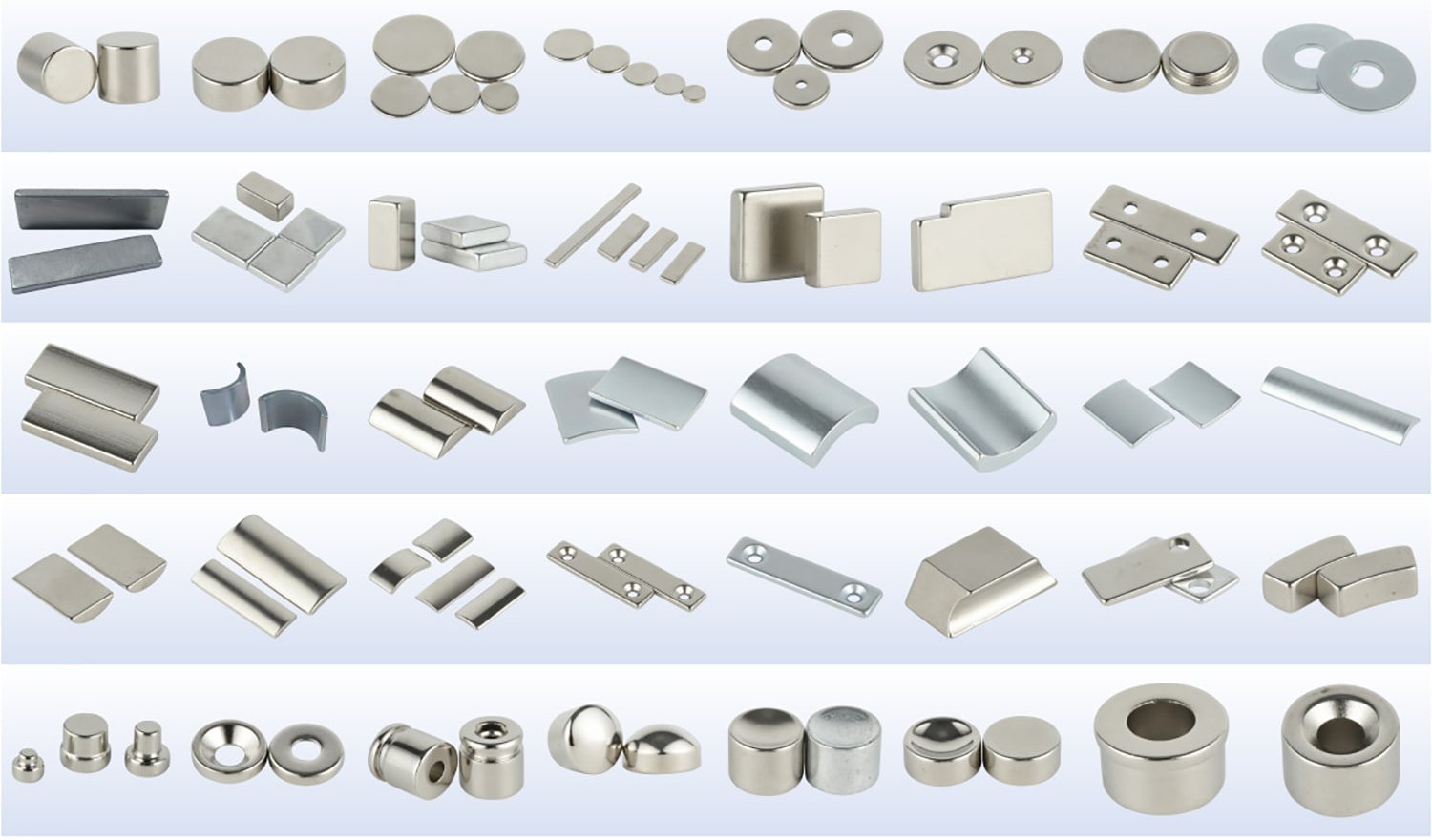

Shape and size:

Rare Earth Magnets NdFeB can be customized in various shapes according to customer needs, such as round, square, rectangular, ring, tile, special shape, etc. The size range is wide, ranging from micro magnets as small as a few millimeters to large magnets as large as hundreds of millimeters.

Color and gloss:

The surface usually appears silver-gray or gray-black, which is determined by the raw materials and manufacturing process of the magnet. Some magnets are plated on the surface, such as zinc plating, nickel plating, epoxy, etc., to improve their corrosion resistance and aesthetics.

High magnetic properties:

Rare Earth Magnets NdFeB has very high magnetic energy product (Br*Hcj) and coercive force (Hcj), which can provide a strong magnetic field. The magnetic properties are stable and not easily affected by the external environment (such as temperature and humidity).

Good mechanical properties:

Magnets have high compressive strength, bending strength and impact toughness, and can withstand certain mechanical loads. Easy to process and cut, drilling, grinding, cutting and other processing operations can be performed as needed.

Application scenarios

Motor field:

Rare Earth Magnets NdFeB is one of the key materials for high-efficiency motors, which can significantly improve the efficiency and performance of motors. It is used in motors in electric vehicles, wind power generation, household appliances and other fields.

Sensor field:

As a key component in the sensor, magnets can sense changes in the magnetic field and convert them into electrical signals. It is used in the manufacture of position sensors, angle sensors, speed sensors and other equipment.

Speaker field:

Magnets provide a magnetic field for the speaker, causing the voice coil to vibrate under force in the magnetic field, thereby generating sound. It is used in speakers in home theaters, car audio and other fields.

Products show

Surface Coating & Corrosoin Resistance

|

|

|

|

| Nickel(Ni-Cu-Ni) | Zinc(Zn) | Black Epoxy | Gold |

| Type | Color | Plating Thickness | Working Temperature |

Advantage & Suitable | Salt Spray Resistance | |||||

| Nickel(NiCuNi) | silver | 20-30 um | ≤200 | high oxidation resistance, good glossiness, stable performance, long service life | > 72 hrs | |||||

| Zinc (Zn) | blue white | 10-20 um | ≤160 | suitable for low requirements for surface appearance & oxidation resistance | > 48 hrs | |||||

| Epoxy | black | 10-30 um | ≤120 | suitable for high anti-corrosion and strict atmospheric environment | > 96 hrs | |||||

| Gold | Gold | 5-30 um | ≤200 | suitable for decoration accessories, gift box etc. | > 24 hrs | |||||

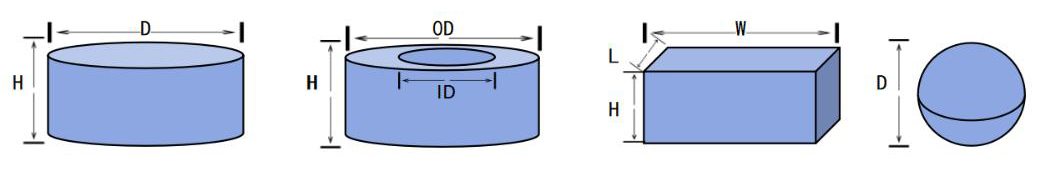

Tolerance

| Standard Product | D.OD | ID | L | W | H |

| <5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

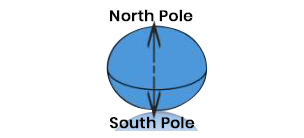

Magnetization Direction

| Disc&Cylinder-through Thickness | Disc&Cylinder-through Diameter | Spheres- through Diameter |

|

Poles on the flat surfaces

|

Poles on the side surfaces |

|

| Block- through Thickness | Block- through Length | Arc- through Diamter |

|

Poles on the larger flat surfaces |

Poles on the smaller flat surfaces |

Poles on outside&inside faces |

| Arc- through Length | Ring- through Surfaces | Ring- through Surfaces |

|

Poles on outside&inside faces |

Planar octupole magnetization |

Planar quadrupole magnetization |

Sintered NdFeB Magnetic Properties

| Grade | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy | Working≤ | |||||||

| Br(KG) | Br(T) | Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) | (BH)max (KJ/ m) |

℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

| Remarks: The maximum working temperature depends on the shape, size, and coating of the magnet, the highest working temperature in the table is the test data for standard sample. | ||||||||||||

In modern science and industry, there is a material known as the "King of Magnets," possessing aston...

READ MOREOn the surface, disk magnets, with their solid center, seem to contain more magnetic material. Howev...

READ MOREMagnetic materials play a crucial role in modern industry and high-tech fields. Among them, neodymiu...

READ MOREDisc magnets, as a common type of permanent magnet, play an important role in our daily lives due to...

READ MOREDisc magnets are becoming increasingly common in our daily lives and industrial sectors due to their...

READ MOREMagnetic materials play a crucial role in modern technology and industry, with Neodymium magnet disk...

READ MOREIn the field of permanent magnet materials, neodymium magnets dominate due to their powerful magneti...

READ MOREIn our daily lives, magnets are present everywhere, from the simple refrigerator clips that hold not...

READ MOREIn modern industry and daily life, there is a class of magnetic materials known as the "King of Magn...

READ MOREIn modern technology, neodymium magnets, known as the "King of Magnets" for their extremely strong m...

READ MORENeodymium magnets, also known as neodymium iron boron (NdFeB), occupy a central position in modern i...

READ MOREIn modern industry and everyday applications, NdFeB magnets are known as the "King of Magnets" for t...

READ MORE